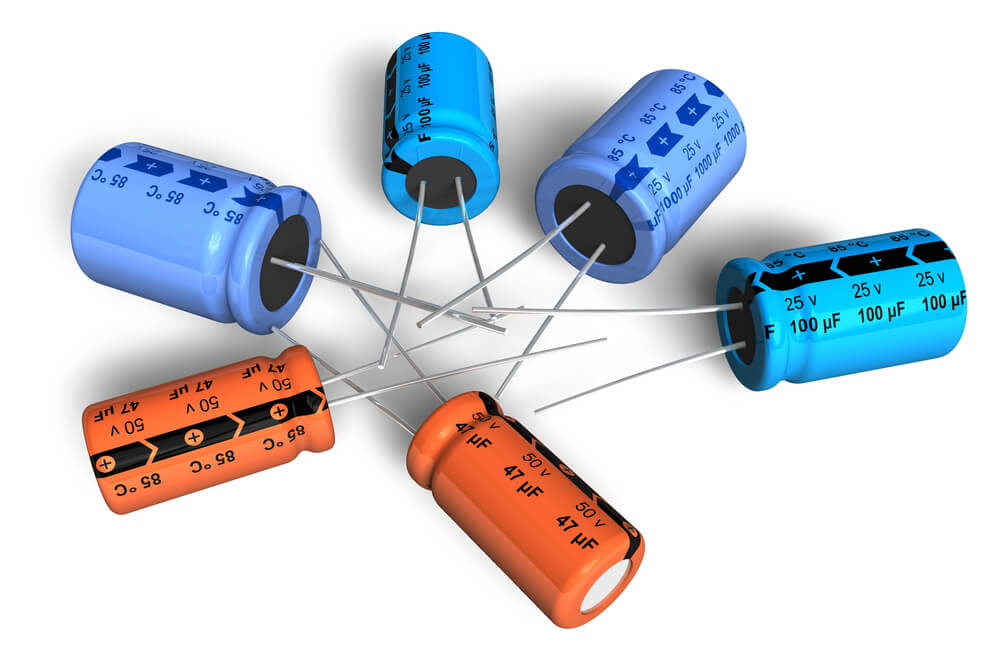

How To Properly Store Capacitors

Capacitor storage is crucial to protecting the devices from damage in storage and shipping. Many factors come together to create ideal storage conditions for capacitors. For example, your packaging should be sturdy and offer adequate protection. Temperature and humidity regulation are also important. Take a look at how you can ensure proper storage conditions.

Provide Physical Protection for Capacitors

Protecting the physical makeup of your components is crucial to proper storage. Factors to consider when choosing a capacitor storage box include capacitor size, materials, and construction. For example, some materials break more easily, while others require humidity controls to prevent corrosion.

The exact type of protective measures you need to take will vary with the type of capacitors you need to store. Some, such as delicate ceramic models, are more vulnerable to damage than others. However, there are a few general rules that can make it simple to find the right capacitor storage solutions that provide adequate protection for your stock.

Protection From Static and Other Interference

Excess static electricity can damage some capacitors, including the commonly used ceramic ones, during storage. In this instance, using anti-static bags or plastic trays made with anti-static materials such as PETG anti-static, HDPE Blue anti-static, ESD polycarbonate, and anti-static PVC. These help prevent electrostatic discharges that could damage sensitive electronics.

Another consideration is ensuring that your storage area is away from any sources of large magnetic fields. Medical facilities and data centers may be more prone to experience this type of interference than other facilities. If you cannot relocate your capacitor storage area, use proper shielding techniques to protect sensitive electrical components.

Protection Against Breakage

Capacitor storage solutions must protect from breakage and other physical damage. This is especially true of smaller units that can be very delicate. Limiting pressure from stacking or compression is important. You should also try to avoid any bending or flexing of capacitor storage boxes.

Impacts can cause physical damage in several ways. They can result in jarring or jostling of components, which can cause cracks or loosen connections. A direct impact can dent or otherwise compromise the case of a capacitor, even a large industrial model. For these reasons, any capacitor storage box should provide at least some level of protection against this type of damage.

Our plastic storage trays are ideal for capacitor storage because they provide each piece with an individual compartment. This reduces the risk of pieces bumping against each other. We offer trays in hundreds of unique sizes and configurations, or you can order custom trays to meet your exact specifications.

Protection From UV Light

While some capacitors, such as those used on outdoor equipment and UV lamps, can withstand sunlight, others need an additional layer of protection. Some plastic and polymer materials degrade in sunlight, which could affect the appearance and performance of capacitors made with them.

It is a good idea to create capacitor storage that filters out most, if not all, UV light. This can help preserve their outer casings and packaging materials. It also helps keep labeling looking new, so you can easily identify specific products.

Maintain Environmental Controls During Capacitor Storage

Proper environmental controls ensure that electronics in capacitors remain functional and able to properly store electrical charges. They also help to preserve the longevity of components. As a general rule, you should avoid extreme storage temperatures. This includes overheating and freezing capacitors. A safe temperature range is between approximately 50 and 100 degrees.

Failure to maintain appropriate temperatures can degrade dielectric material in capacitors, especially under prolonged storage. This degradation reduces the performance and longevity of electrical components.

Humidity is another consideration in controlling the environment of capacitor storage. You should take steps to keep capacitors relatively dry, with ideal humidity levels below 60%. This will reduce corrosion, which can cause leaks or interfere with conduction. Vacuum sealing or placing desiccants within capacitor storage boxes can help control moisture in humid storage environments.

Properly Organize Capacitors

Organization is key to any storage solution. With capacitors, it ensures products are used in a timely manner so that you can observe any shelf-life limitations. Bins and trays are ideal for creating organized storage systems because they allow you to group products according to specific characteristics. Some examples include sorting capacitors by:

- Capacitance ratings

- Size

- Type

- Voltage

Another consideration is stacking. Even heavy-duty industrial capacitors can bend or break. Stacking or piling them creates extra opportunities for this to happen. Using trays with pockets can help keep capacitors organized and secure during storage.

Once you have the items categorized, you can use racking and shelves to hold smaller bins. This reduces the risk of damage from stacking boxes of loose components.

Labeling

You also want to find a system that allows you to label and sort capacitors into specific categories. Proper labeling helps minimize the risk of accidentally using the wrong capacitor. It also streamlines placing and managing inventory. For manufacturers, it reduces the chance of picking and shipping the incorrect product from your warehouse. You can add labels directly to capacitor packaging, storage trays, boxes, or shelving units.

Accessibility

Accessibility is an important component of organizing your capacitor storage. No matter what size products you are dealing with, a capacitor storage box should allow you easy access to the exact part you need.

Our storage trays have individual compartments that keep each product secure and easily accessible. Additionally, they fit inside standard box dimensions, making them ideal for packaging and labeling larger quantities. You can also use the trays as secure and lightweight packaging material for shipping capacitors.

Shop Ready-Made Plastic Trays for Capacitor Storage Solutions

Ready-Made Plastic Trays are ideal for capacitor storage. They provide physical protection from impacts, jostling, stacking, and static electricity. They also make it simple to organize and access your stock. We manufacture over 200 standard sizes and styles of packaging trays, with many models in stock and ready to ship. We can also provide custom trays to your exact specifications with a short turnaround time. Contact us to request a free sample.

.jpg?length=328&name=Depositphotos_185373910_S%20(1).jpg)