Thermoforming vs. Vacuum Forming

When it comes to shaping plastic for various applications, two popular methods are thermoforming and vacuum forming. Both offer unique advantages depending on the type of product you need to create. When deciding which process is best suited for your product, it's essential to understand the differences between thermoforming and vacuum forming. By knowing the strengths and limitations of these plastic shaping methods, you can make an informed choice that best suits your product specifications, production timeline, and budget.

What Are Thermoforming and Vacuum Forming Used For?

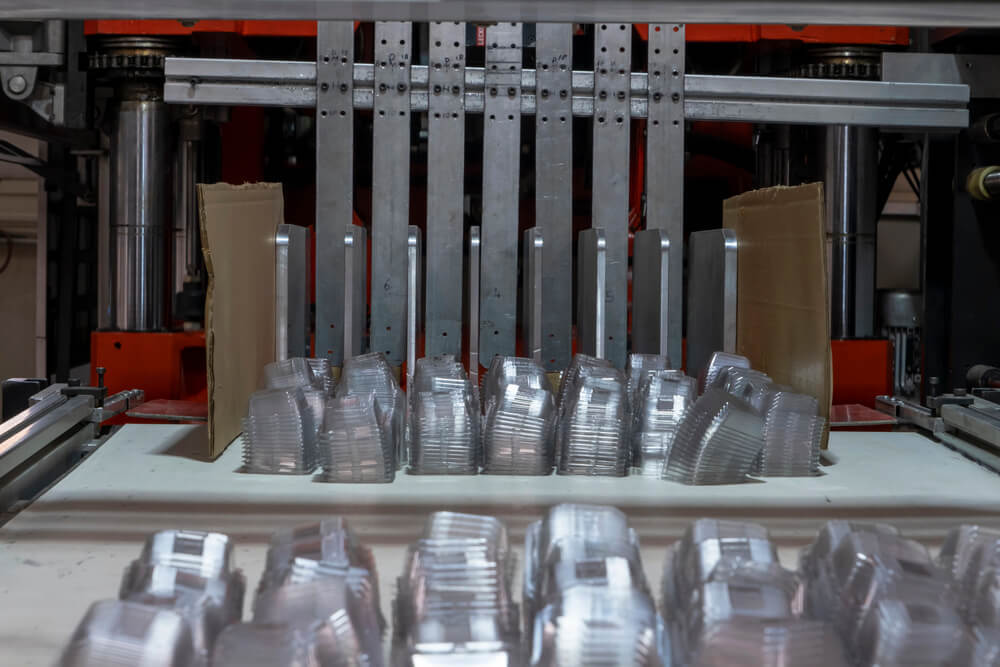

Thermoforming and vacuum forming are both widely used processes for manufacturing plastic products. Both involve heating a sheet of plastic until it becomes soft and pliable, then molding it into a specific shape.

These methods are ideal for producing items that need to be lightweight, durable, and cost-effective. Some examples include:

- Plastic Trays: Lightweight and sturdy, often used for packaging products or organizing components in industries like automotive, foodservice, and optics.

- Packaging: Commonly used for retail products, clamshells, and blister packs, providing protective and clear containers for various items.

- Automotive Parts: Dashboard components, interior panels, and trim parts are often manufactured using thermoforming for their durability and cost-effectiveness.

- Medical Device Components: Includes items such as sterilization trays, diagnostic equipment components, and custom packaging for sensitive medical products.

- Food Containers: Clear, disposable containers for packaging food, often used in supermarkets and fast-food chains, ensure safety and easy storage.

These plastic forming techniques are also used in creating custom designs for a wide range of industries.

What Is the Thermoforming Process?

Thermoforming involves heating a plastic sheet until it becomes soft enough to be stretched over or into a mold. The sheet is then pressed or stretched into the desired shape using various techniques. The most common methods of thermoforming include:

- Pressure Forming: This technique uses high pressure to force the plastic into the mold, resulting in sharp detail and a high-quality finish. This is ideal for products that require intricate shapes or fine details.

- Plug Assist Forming: In this method, a plug is used to help stretch the plastic into the mold, improving the quality and depth of the final product. It is especially useful for deeper or more complex molds.

Thermoforming is known for its versatility, as it can work with a variety of plastic materials, including ABS, polystyrene, PET, and PVC. It is especially efficient for producing products in larger quantities at a lower cost compared to other manufacturing techniques, such as injection molding.

One major benefit of thermoforming is that many types of thermoformed plastics are recyclable, making thermoforming a more sustainable choice in the manufacturing process as industries strive to reduce their environmental impact.

What Is the Vacuum Forming Process?

Vacuum forming is a type of thermoforming that uses a vacuum to draw a heated plastic sheet over a mold. The plastic sheet is placed on top of the mold, and once it’s heated to a pliable temperature, a vacuum is applied to suck the material into the mold’s shape. This process is quick and efficient, particularly for producing shallow parts or items with simpler designs.

Vacuum forming typically uses thinner plastic sheets compared to other thermoforming techniques. It is commonly used for packaging, point-of-sale displays, and trays for food and medical industries.

What’s the Difference Between Thermoforming and Vacuum Forming?

Thermoforming and vacuum forming share many similarities, but understanding their differences can save time, reduce costs, and ensure the product meets quality expectations. The most notable differences are in cost, output quality, and the type of products they are best suited for.

Thermoforming

Thermoforming is a versatile plastic manufacturing process that excels in producing parts with more intricate designs and deeper molds. While it is generally more expensive than vacuum forming due to its ability to handle more complex shapes, it offers superior precision and customization options, which can justify the higher cost.

Pros

- Versatile: Can handle deep, complex molds and a wide variety of materials.

- High-Quality Finish: Especially with techniques like pressure forming, it produces precise, detailed, and polished results.

Cons

- Higher Costs: The process is more expensive, particularly for intricate or large parts.

- Slower Production: Compared to vacuum forming, it generally requires more time and effort due to the complexity of the molds and materials used.

Vacuum Forming

Vacuum forming is generally more cost-effective and quicker than thermoforming, especially for large-volume, low-cost production. It uses thinner plastic sheets and a simpler process, making it ideal for creating shallow parts and large quantities at a faster pace. However, while it’s more affordable and efficient, the quality and complexity of the final product can be lower, making it less suitable for products that require fine details or intricate designs.

Pros

- Cost-Effective: Lower material and tooling costs, making it ideal for high-volume, low-cost projects.

- Faster Production: Quicker cycle times due to the simpler process and thinner materials.

Cons

- Limited Complexity: Best suited for shallow parts with simple designs; struggles with intricate or deep molds.

- Lower Quality: Parts may lack the precision, strength, and finish of those produced by thermoforming, making them less suitable for detailed or high-end applications.

Thermoforming vs. Vacuum Forming: Which Is Better?

Neither thermoforming nor vacuum forming is inherently better than the other. Both have been in use for a long time and are widely recognized. The right choice depends entirely on the specific needs of your product. If you need large, shallow parts at a low cost and high speed, vacuum forming may be the ideal solution. On the other hand, if your project requires more detailed or complex designs, thermoforming offers greater flexibility and precision.

Ready-Made Plastic Trays specializes in thermoforming to create custom plastic trays and packaging materials for a wide range of industries, including aerospace, automotive, and medical. Our thermoforming processes ensure that we produce durable, high-quality plastic components tailored to your specifications and needs.

Ready to elevate your product packaging? Get a quote for our custom plastic packaging solutions today and discover how we can help you choose the best method between thermoforming and vacuum forming to create durable, high-quality packaging tailored to your needs.